etavat

etavat

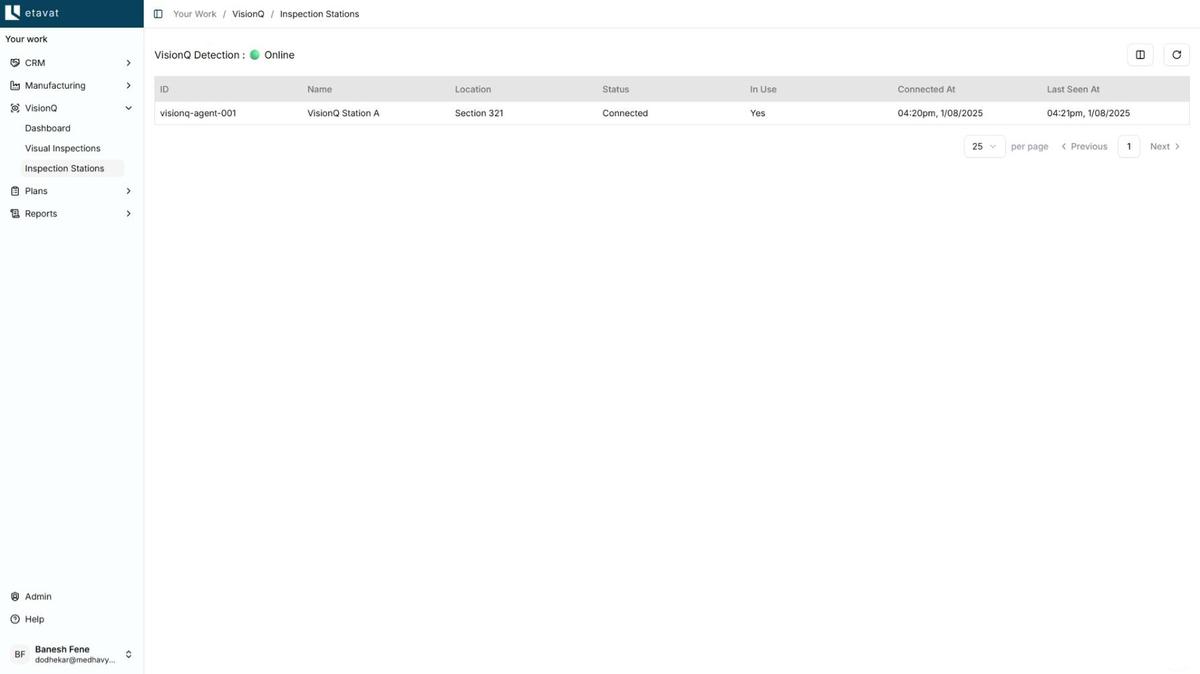

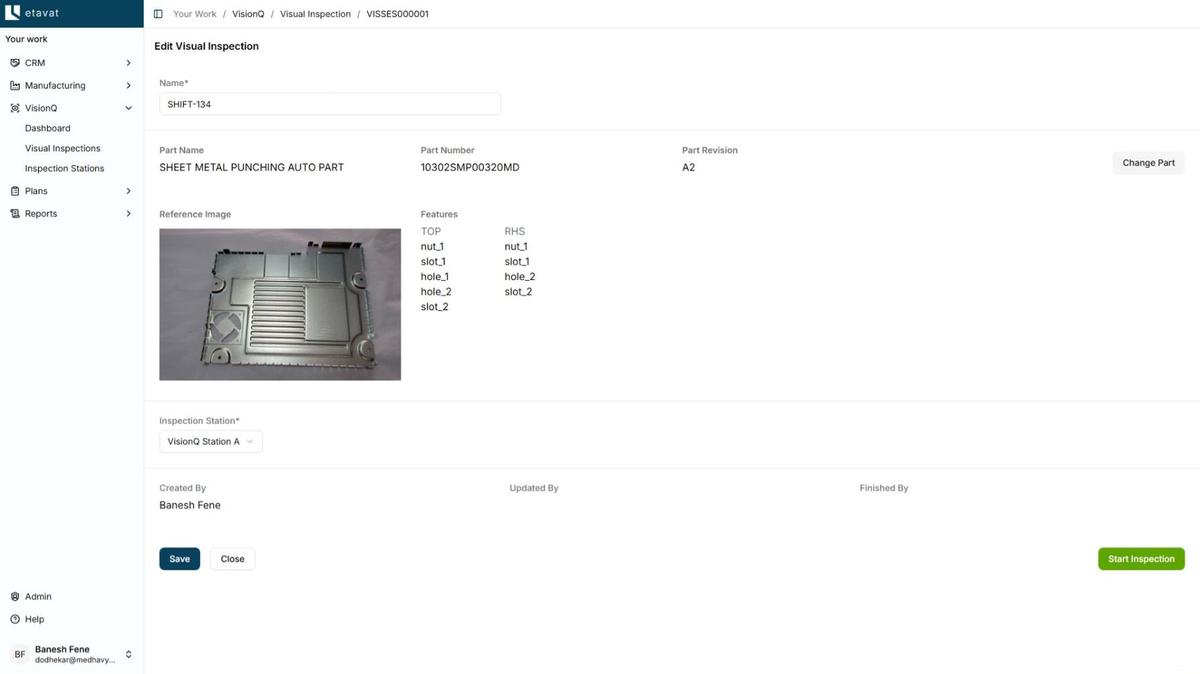

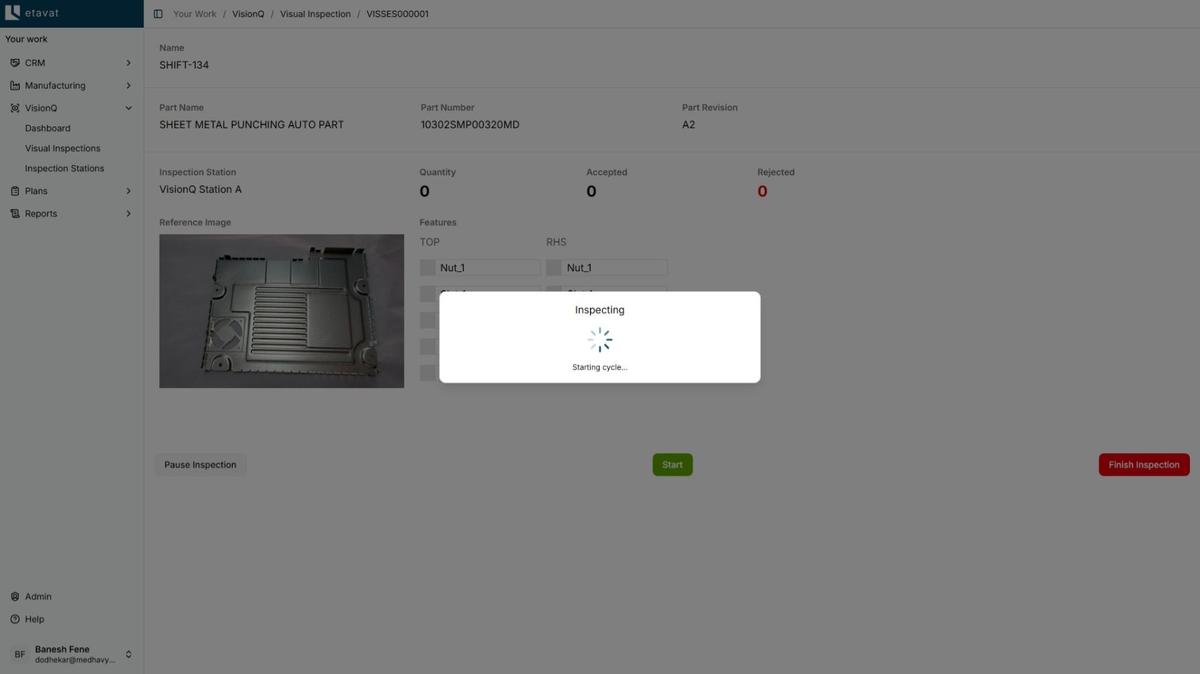

VisionQ

Precision Visual Inspection, Powered by Intelligence

VisionQ is an advanced visual inspection solution designed to automate and elevate defect detection in manufacturing environments. With high-accuracy detection of critical defects such as holes, studs, nuts, and spatter, VisionQ ensures consistent quality control without slowing down production. Seamlessly integrating with your workflow, it combines the power of computer vision and smart algorithms to deliver real-time insights and zero-compromise accuracy.

Key Features

- Automated Defect Detection Detects holes, studs, nuts, and spatter with precision—reducing human error and oversight.

- Real-Time Quality Insights Provides instant feedback on visual defects to catch issues early and minimize rework.

- Scalable and Flexible Adapts to various components and inspection setups, making it suitable for diverse production lines.

- Smart Learning Capabilities Built on AI/ML models that improve accuracy over time with continued usage.

- Reduced Inspection Time Accelerates inspection processes while maintaining consistent, repeatable results offering upto 85% faster inspection

ROI

- Up to 70% cost savings

- Reduced dependency on skilled inspectors.

- Fewer false negatives

- Quality rejections

- Quicker feedback loops and process adjustments.

- Consistent, unbiased inspection

- Digital defect records for traceability

- Integration-ready with MES, PLCs, QMS

etavat

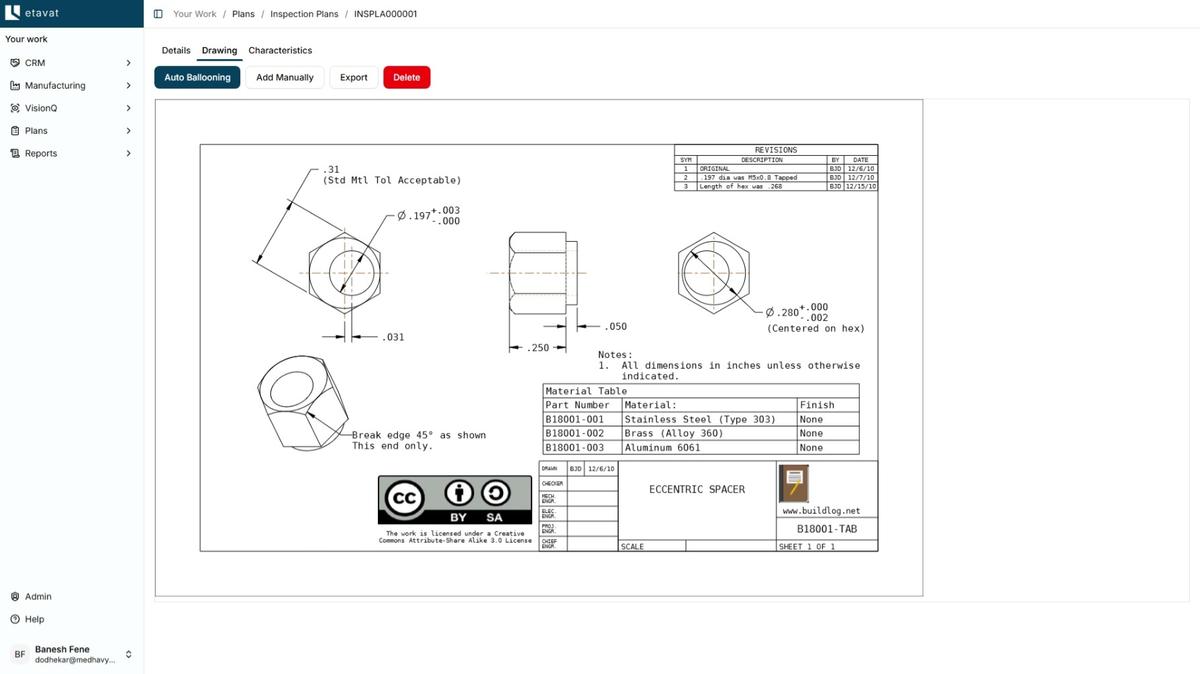

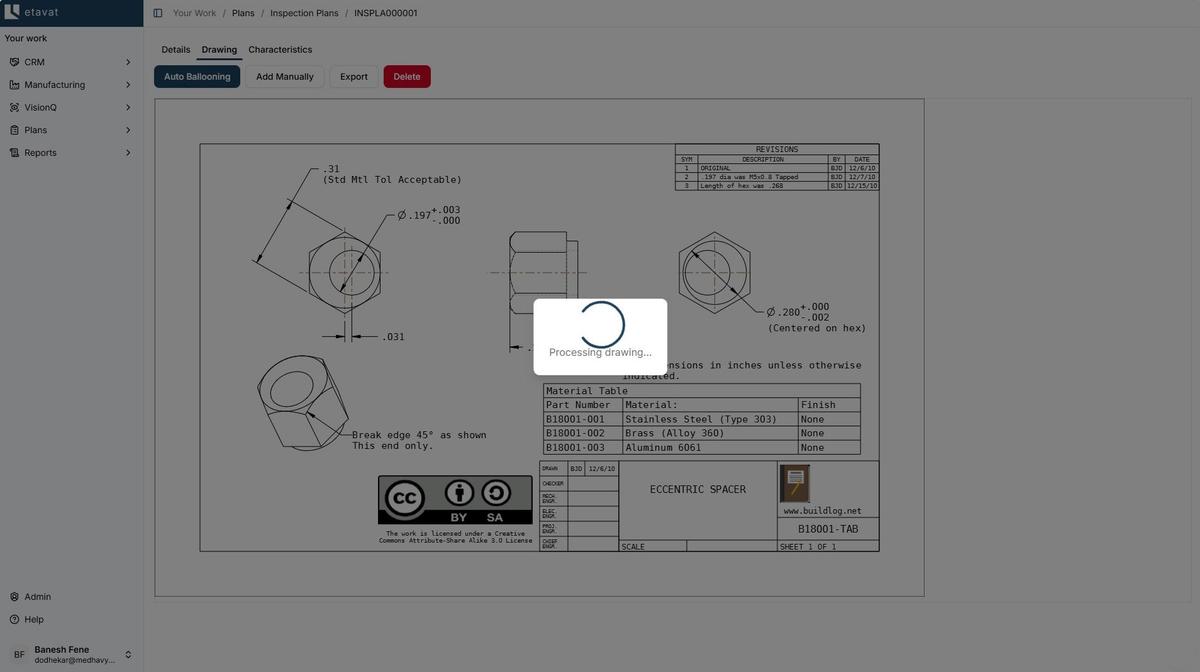

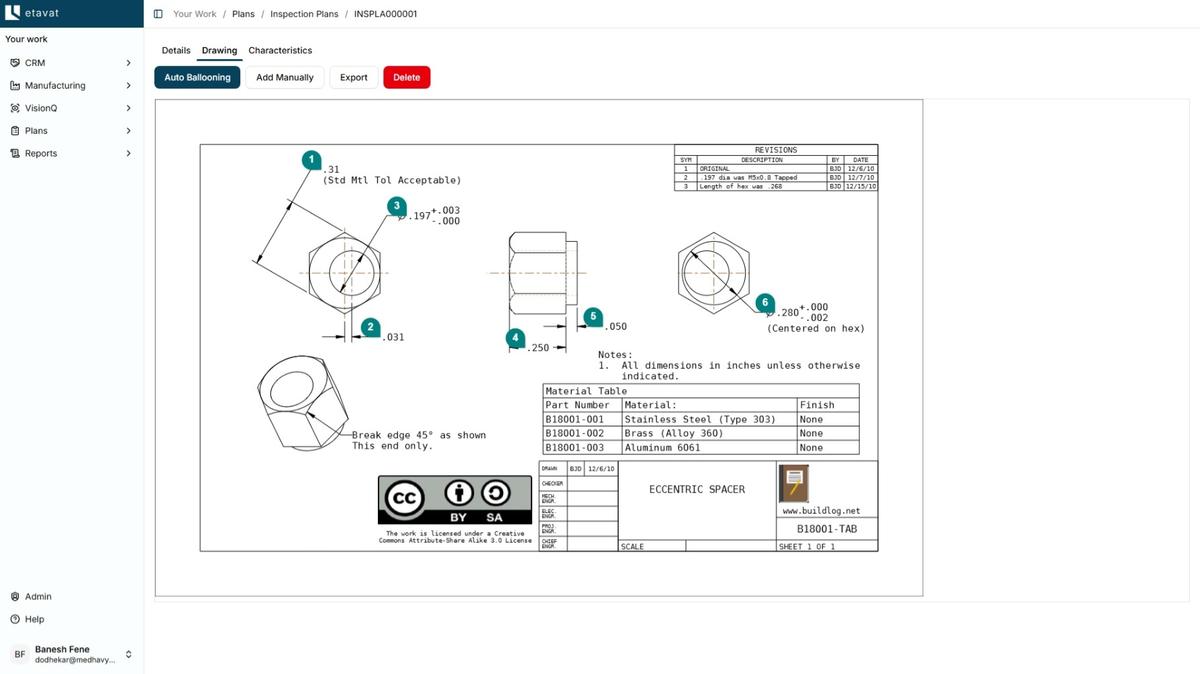

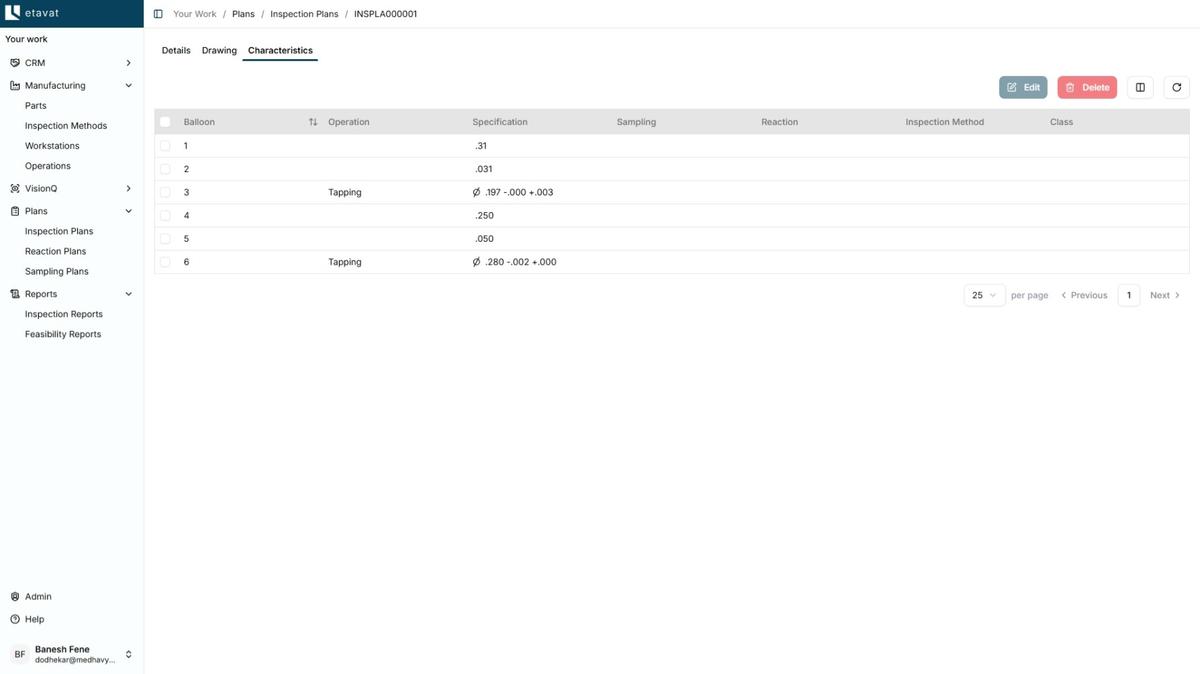

DrawingQ

Accelerated Productivity, Automated by AI

DrawingQ is a smart auto-ballooning tool. It helps streamline the creation of inspection reports from engineering drawings. With just a few clicks, it identifies and balloons critical dimensions, tolerances, and notes. It then automatically generates precise inspection reports in both spreadsheet and PDF formats. DrawingQ enhances productivity. It reduces manual errors and accelerates quality documentation. All of this is done while maintaining compliance with industry standards.

Key Features

- Accelerated Inspection Planning: Drastically reduces the time to generate ballooned drawings and inspection reports.

- Improved Accuracy: Minimizes human errors with automated capture of dimensions and tolerances.

- Professional Outputs: Exports polished, standardized reports in Excel and PDF formats.

- Seamless Compliance: Supports quality documentation aligned with ISO, AS9102, and IATF standards.

- User-Friendly Interface: Intuitive workflow that integrates effortlessly into existing quality processes.

ROI

- Time Savings

- ~80% reduction in time spent ballooning drawings manually (From 1–2 hours per drawing to ~10–15 minutes)

- 50–70% faster inspection report generation (Excel/PDF output auto-generated, no re-entry of data needed)

- Cost Reduction

- Up to 60% lower labor costs in inspection planning (Fewer hours spent by quality engineers on repetitive tasks)

- Reduced rework costs by up to 30% due to error-free extraction of GD&T and tolerances

- Productivity Boost

- Enables handling 2–3x more drawings per day per quality engineer

- Frees up resources to focus on value-added activities like root cause analysis and quality improvements

- Compliance & Quality Gains

- Standardized outputs reduce audit preparation time by up to 40%

- Supports seamless integration into APQP/PPAP workflows, improving compliance traceability

coming soon

etavat

Integrated Quality Management System

Etavat by Medhavyn is a smart, integrated Quality Management Software designed to streamline and automate APQP and PPAP processes. Built to support compliance with IATF 16949 and ISO standards, QMS ensures full traceability, structured change management, and real-time collaboration across teams. From FMEA to Control Plans, it brings precision, consistency, and speed to your quality workflows; so you can deliver better products with confidence.

Key Features

- Minimized rework from outdated documents

- Reduced audit penalties and non-conformities

- Lower effort for compliance documentation and approvals

- Centralized repository for all PPAP/APQP documents

- Role-based access for secure collaboration

- Integration-ready with ERP, PLM, and MES systems

- Instant visibility into quality status across programs

ROI

- Up to 65% cost savings

- Up to 75% time saved on document creation

- Up to 80% faster execution of change management effort

- Full compliance readiness